Versatile and cost-effective, injection molding produces parts that serve an array of purposes.

To get the most out of your injection molding project, you need skilled operators, communicative and knowledgeable project managers, and customer-centric logistics.

Quickparts’ multiple U.S. manufacturing facilities mean we can begin your tooling the same day we receive files. Faster tooling time helps save you time and money by delivering your project wherever and whenever you need it.

We assist our customers with a design-for-manufacturing review to determine whether files need design adjustments before moving the project to production. This helps you obtain the best possible result with your project and gets your parts and products to market faster.

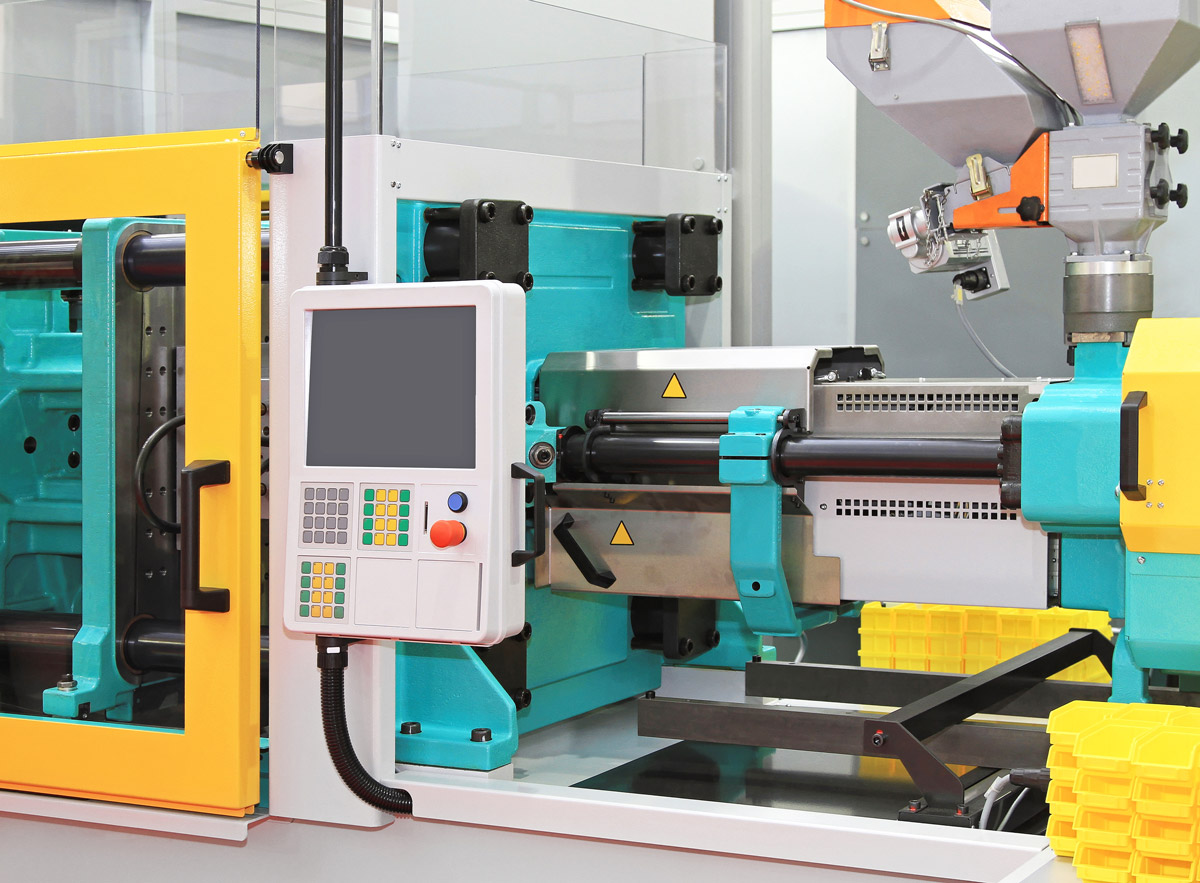

How it Works

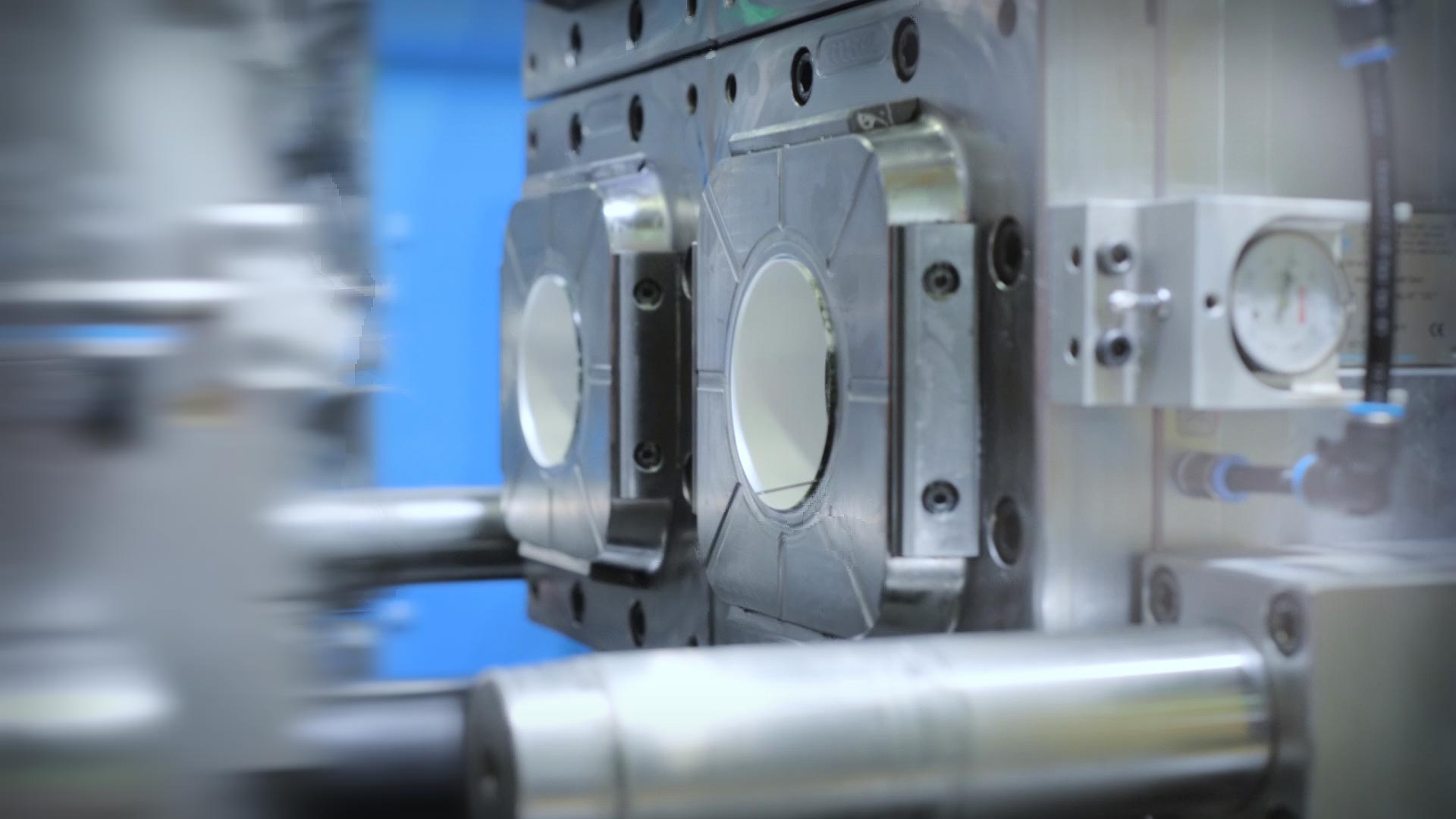

Injection molding is the process of forcing heated thermoplastics into a mold cavity to create a desired component. .

Using injection molding, Quickparts offers a large variety of solutions and benefits to meet your needs, from rapidly manufactured prototypes to low-volume production services, even for projects with challenging geometries.

Learn More with our injection molding design guidelines.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is the pioneer of on-demand manufacturing

Quickparts is the pioneer behind the first digital manufacturing platform, offering on-demand services for both additive and traditional manufacturing. Through QuickQuote, our on-line customer portal, we offer instant quoting service for SLA, SLS, DLP, and CNC parts, featuring various lead times to align with your project’s delivery and budget needs. For all other processes. QuickQuote enables you to upload your CAD and submit requests for quotes and we’ll do our best to respond within 2 hours.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.

Injection Mold Tooling Services- Hire Our Manufacturers

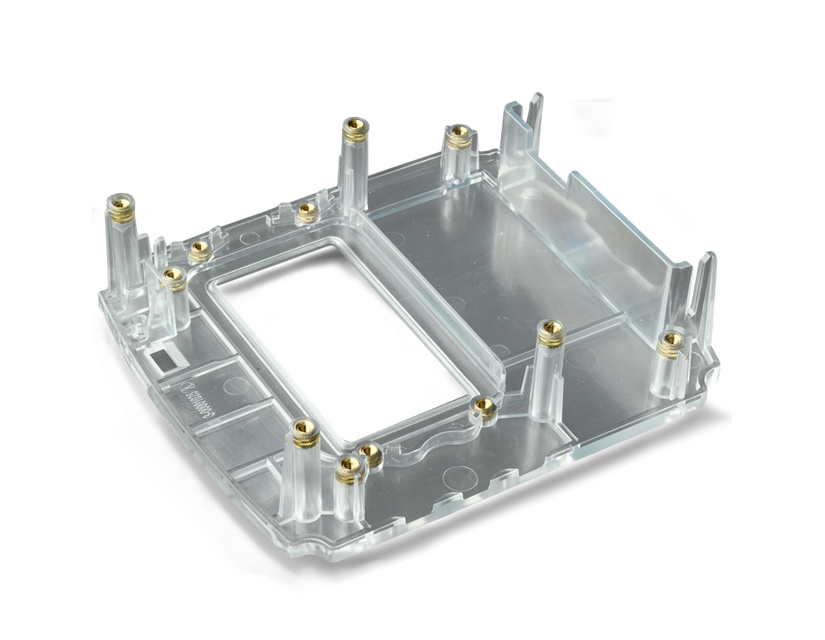

Are you looking for an Injection Mold Tooling partner? By using Injection Molding for your tool, you will be able to have a finished product with high quality and one that is highly cost effective.

How do our injection molders help you?

At Quickparts, we fabricate molds from the best quality materials to fulfill your dimensional requirements. Our unique approach ensures repeatability while operating the process at high speeds. In addition, our molds always adhere to industry standards. As a result, our production cycle time is fast, and we deliver the output within the shortest period.

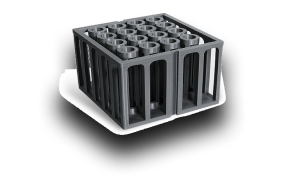

We always make a streamlined approach to mold making, plastic injection molding, and engineering processes. We have a separate team of quality control specialists who understand the importance of value, quality, and consistency in molded products. This is how we can differentiate ourselves from our competitors. Our injection molding parts manufacturer helps you with

- Overmolding

- Hot runner molds

- Insert molds

- Highly intricate

- Multi-cavitation tooling that holds close tolerances

We can also offer stack molds where the molding faces are stacked together. Moreover, we make multi-level injection mold part production using the stack molding process. Our professionals are efficient at making 2 to 3-level stack molds. In addition, our professional team of engineers ensures that your stack molds effectively serve your purpose.