Sheet Metal

Sheet metal provides strong, dependable solutions for various applications.

Finding the right manufacturer to create your sheet metal parts is crucial, so look for a partner with experience, quality engineers, and well-managed facilities.

Quickparts is your partner for all your traditional and additive manufacturing needs. Our global team of professional engineers and network of facilities delivers quality parts to you when and where you need them.

How it Works

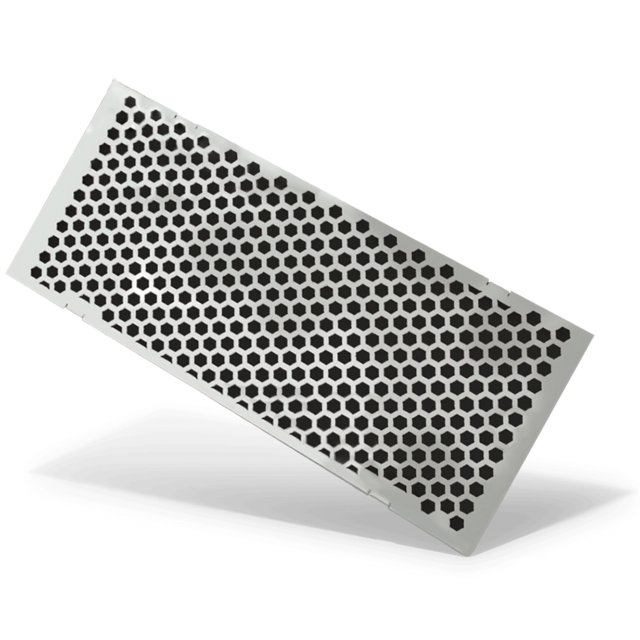

Sheet Metal services come in a variety of capabilities such as bending, shearing, staking, and stamping. These parts are commonly used in drilling, tapping, counterboring, and countersinking operations. Sheet metal parts can fit many projects, from simple bent sheet metal prototypes to production runs of complex, multi-part assemblies.

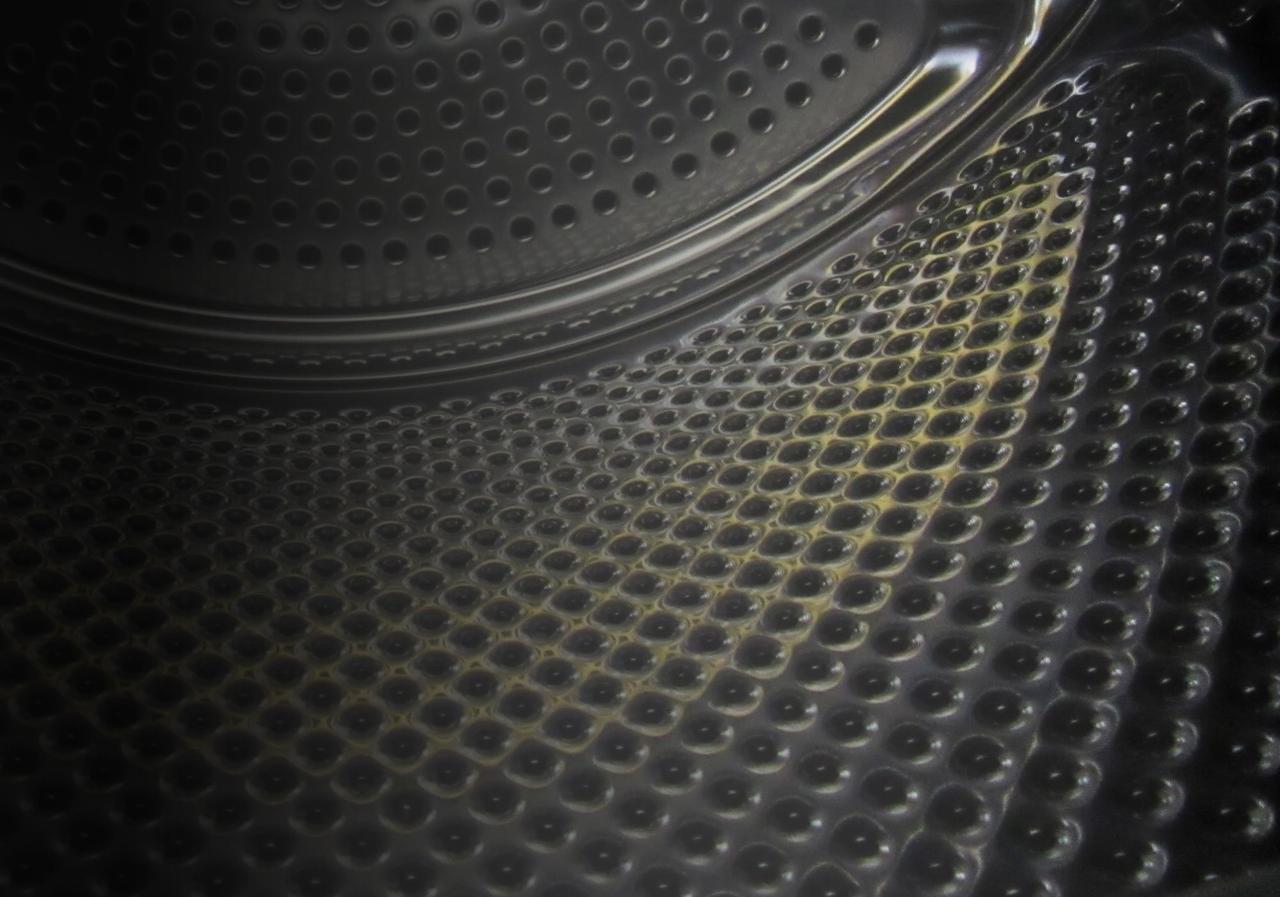

Quickparts produces sheet metal parts through laser cutting, water jet, or chemical etching processes to form blanks from sheet metal stock. These blanks are then bent to shape using press brakes or quick custom tooling to form the final geometry. We support all your sheet metal services with our state-of-the-art sheet metal fabrication facility that includes vertically integrated metal forming, laser cutting/punching, CNC machining, welding, and finishing cells to support both prototype and production runs of high-quality sheet metal enclosures and housings.

Let us be your resource to determine which manufacturing process is right for your project.

About Quickparts

Quickparts is a pioneer in the 3D printing world.

We are the originator of a full digital manufacturing platform that delivers on-demand additive and traditional manufacturing services. From rapid prototyping to appearance models and volume production, Quickparts operates the most advanced technology and possesses the expertise to handle any additive manufacturing project.

With facilities stationed around the world, each staffed with experienced engineers laser-focused on meeting your specific requirements as effectively and quickly as possible, you can trust Quickparts with all of your manufacturing needs.

Get Started

You’re seconds away from starting your Quickparts project.

Sheet Metal Services- Manufacture Any Part Using Sheet Metal

Sheet metal has a range of applications in different manufacturing sectors. But how do you create your sheet metal parts? The sheet metal pieces need to be customized to your needs. This is where our engineers can come to your help.

We can help you with sheet metal bending, stamping, shearing, and staking.

Sheet metal bending

Bending is one of the aspects of the sheet metal manufacturing process. We work on the metal piece to conduct the bending process. Our professionals use different tools and techniques to process flat sheet metal. At Quickparts, we apply die-tooling and press brake punches to twist and stretch the piece into the desired geometry. If form and function are your priority, we recommend sheet metal prototyping. Most commonly, we design sheet metal parts like brackets, enclosures, assemblies, and cabinets. We are also able to convert flat sheet metals into 3D shapes.

How do we bend your sheet metal?

Our team is trained enough to apply different techniques to bend the sheet metal. You can create unique products using sheet metal.

For instance, we use a pressure brake tool to apply coining and air-bending processes. Again, folding is a way to deal with large metal sheets. We also choose the rotary bending process for delicate surfaces.

Our specialty manufacturers are aware of different innovative processes apart from bending. We can work on metal sheets of different thickness levels. The thickness of some sheets is more than 0.25 inches. Based on the chosen metal, we apply the sheet bending processes. Most commonly, our professionals have chosen stainless steel, brass, carbon steel, aluminum, copper, and specialized alloys.

Metal stamping services

We use the dies and a stamping press to transform the metal piece into the right shape. We try out different tools and the die surface until we achieve this shape. Die is the tooling intended for creating the final version of the workpiece. The manufacturing method is effective in dealing with high to medium-volume metal part production projects. You will get the stamped metal pieces at the most affordable price.

We apply different types of metal stamping techniques-

- Blanking- It involves the elimination of the workpiece from the main material to design the desired shape.

- Punching- Punching is a way to use a punch and a die to cut sheet metals into multiple pieces.

- Coining- After placing the material between a press and a die, we squeeze it with force. It enables us to produce a number of features on the surface.

- Flanging- The flanged part of the die and the tooling create the desired shape.